It was hard to measure it exactly.

Basically what i was trying to say is at the aperture (Right after the lens) the beam is:

5mm +/- .1mm

by

1mm to possible 1.2mm

If anyone has a method of measuring after the aperture with more accuracy i would love to hear it and i will give it a try to get better numbers.

The issue i was having is the beam is so bright that its hard to tell. (You have to measure at near to full power as with the FAC lens on the diode or frankly most multi mode diodes you can see that the higher currant you go up the more "Modes" open up making the beam larger) So to get Exact numbers the laser must be turned on full.

This is the lens i used:

http://www.thorlabs.com/thorProduct....umber=LA1213-A

I have on order the 100mm FL to see what difference it makes:

http://www.thorlabs.com/thorProduct....umber=LA1207-A

As well as the 1 inch dia version at 75mm:

http://www.thorlabs.com/thorProduct....umber=LA1257-A

In my experience with dealing with FAC diodes from 445nm,635nm and especially the 650nm ones - the 1/2 inch size lenses give the best results.

However i will be trying next to find a lens that is 50mm FL with a Dia size of 8-9mm. Iam thinking that if the beam uses more of the lens area up and not more of just the center that it will help shape the beam better. Weather it will change or not iam not sure but I Noticed a difference using a 1 inch diameter lens to a 1/2 inch dia. lens. The beam looked sharper and the "Dot" was smaller.

They where the exact same lens shape, same Focal length but there size in Dia was the only difference. The 1/2 inch was tighter.

Iam no expert in optics but love to try things out.

The beam is not that bad.

Me and another member about a year ago had a lab put some FAC Lenses "Micro Lens" On the Mitsubishi 638nm 300mW G71 diodes. The Results where Worse then what this diode does.

I still have the diode somewhere in my stock.

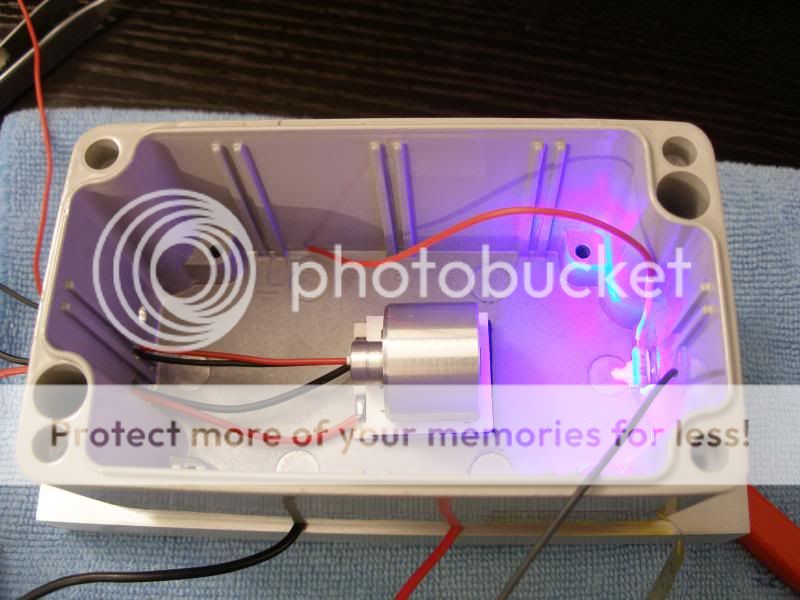

I Also Recently DIYed a 445nm diode and added a FAC lens to it.The lab wanted 400$ + a 2 month wait to get it done and i dint want to wait. (The Guy that did us the favor in the lab did it as a side job for the 635nm 300mW G71 diodes because the other member new him. However he no longer works at the lab so full price has to be paid now.

which stinks)

http://laserpointerforums.com/f42/i-...diy-81547.html

Though not as pretty looking as the professional labs do it with all the right tools it still performs Perfect.

The Results where also very good.

I did not have a chance to do any extensive testing yet because i just got back from dealing with a close death in the family.

But i will try to keep up with everyone.

Thank You.

Reply With Quote

Reply With Quote

It is very basic but alot of trial and error.

It is very basic but alot of trial and error.