Update:

Managed to insert file using XP.....so here it is

I also have more logs which I will post later using different ambient temperatures with the help of an air conditioner. This is just the clearest one I made the first day once I had the test rig set up.

However my latest idea to try a 110vac input will have to wait since all my trafos are a hundred kilometers away in Barcelona and I am up to my ears in work in a village up the coast on the Costa Brava right now.

Cheers

Reply With Quote

Reply With Quote 300EVIL

300EVIL

Unless it's just completely shutting off on it's own at the end of the graph there....

Unless it's just completely shutting off on it's own at the end of the graph there....

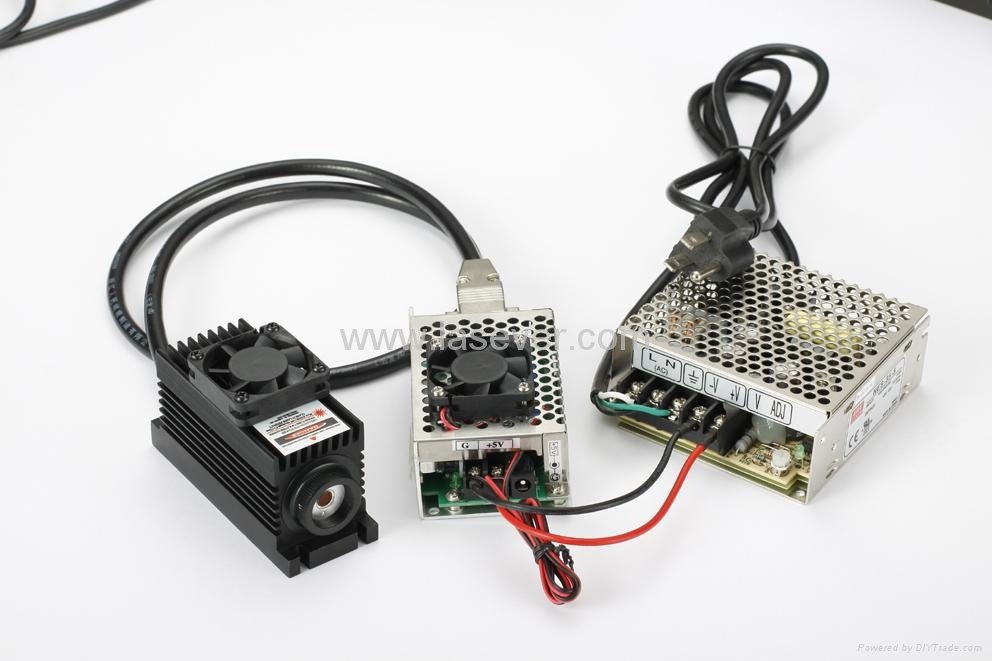

All this would be a piece of cake if someone could give me a guided tour of the DHOM PSU in question.

All this would be a piece of cake if someone could give me a guided tour of the DHOM PSU in question.

This would tend to confirm the failing TEC diagnostic.

This would tend to confirm the failing TEC diagnostic.