Originally Posted by

Things

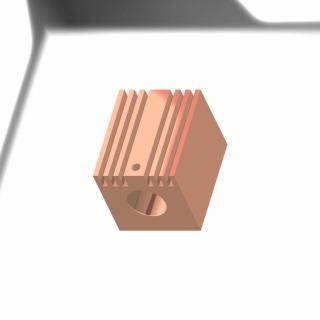

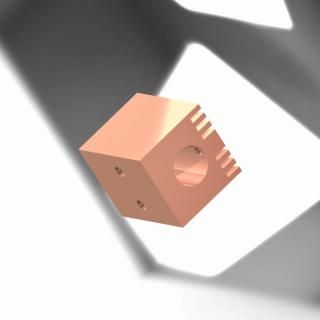

Sorry but, why use set screws?? You're going to the expense of making them out of copper for best thermal conductivity, the minimal contact to the module using a set screw completely F@cks your thermal conductivity ..

You would be better off either making them a direct press solution (Or even back-screw, or somehow allowing the module to screw into the heatsink. Alternatively, you could also clamp the module in, but it's a bit less practical with such a wide heatsink.

Sorry if I come off a bit harsh, but it annoys me seeing so many people aiming for the best thermal conductivity they can get, blowing big money on copper, then doing something really simple that completely defeats the purpose.

All true.

The aixiz module has a poor finish and OD tolerance. Thermal grease is not a large area filler. The module is brass with a zink plating. Brass has poor thermal stats to begin with then plate some zink on top of that, then grease then copper.

That adds up to a lot of thermal resistance. The big problem is at the module/copper mating junction. Draw two circles. One inside of the other. With one slightly smaller. You will see that the contact area is going to be small.

Any way just something to think about.

chad

chad

When the going gets weird, the weird turn pro.

Reply With Quote

Reply With Quote