You're going wild with the metalworking tools eh Andy? Cool stuff. Do you do custom jobs - e.g. a galvo mount to a specific height?

You're going wild with the metalworking tools eh Andy? Cool stuff. Do you do custom jobs - e.g. a galvo mount to a specific height?

currently I own 3x cnc mills and one manual mill.

but I am selling one of the cnc's ;-)

I can do yes, but something to bare in mind is cost of one off jobs, it takes time to code things up

Eat Sleep Lase Repeat

.. and time is money.. I def know that. I charge 5X for my time when I'm off the clock

all the require really is a proper drawing in something like a pdf and I can machine stuff up

Eat Sleep Lase Repeat

I used to do detailing (drafting) by hand in the 70's but almost nothing in CAD in many years .. I may hit 'cha up 1 day for an estimate for a custom piece if you don't mind (and if I can afford it lol)

yeah no worries, one big challenge will be getting that slot done - eg how you clamp the galvo in the mount

I don't own and have never used a slitting saw

Eat Sleep Lase Repeat

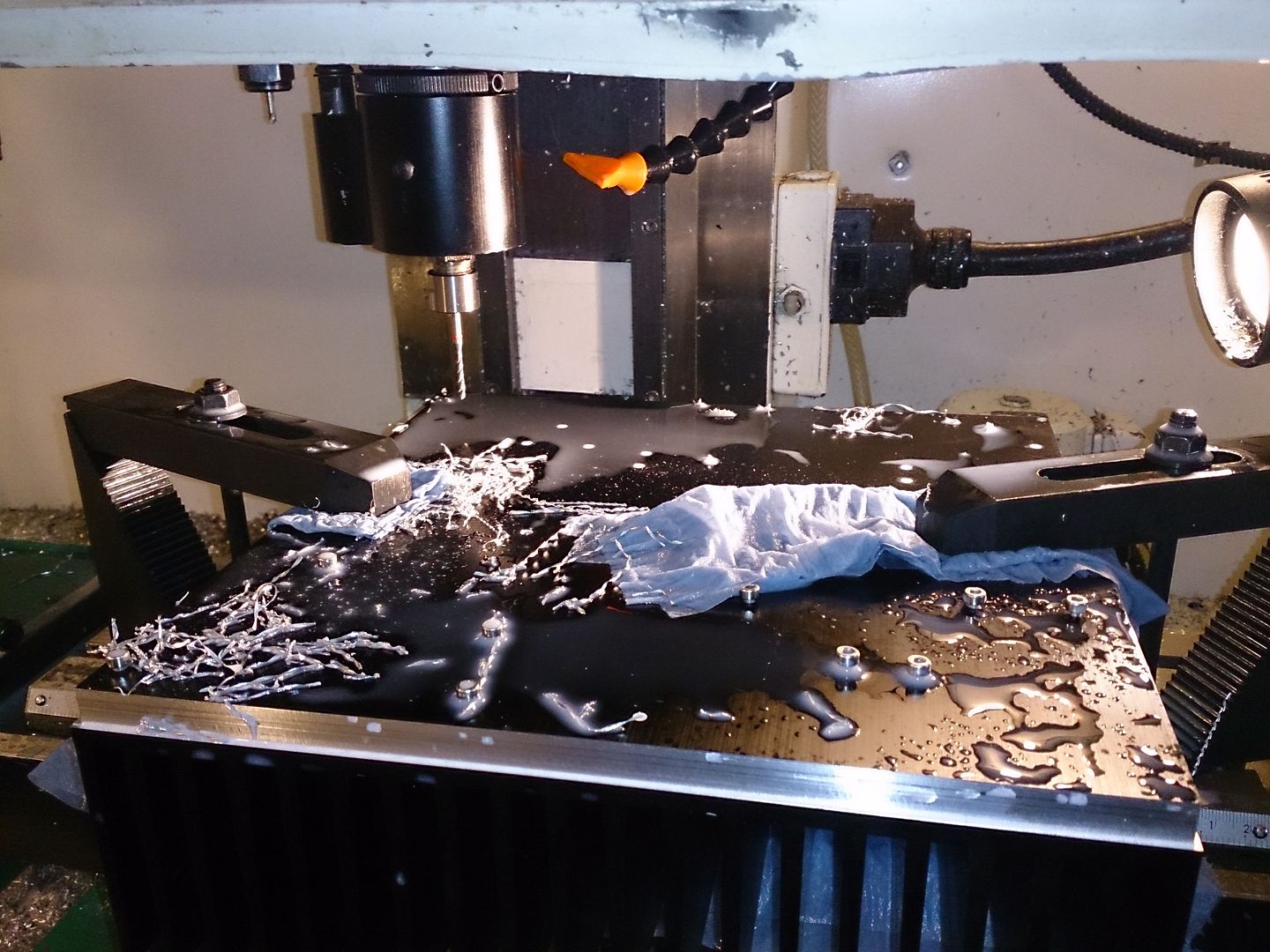

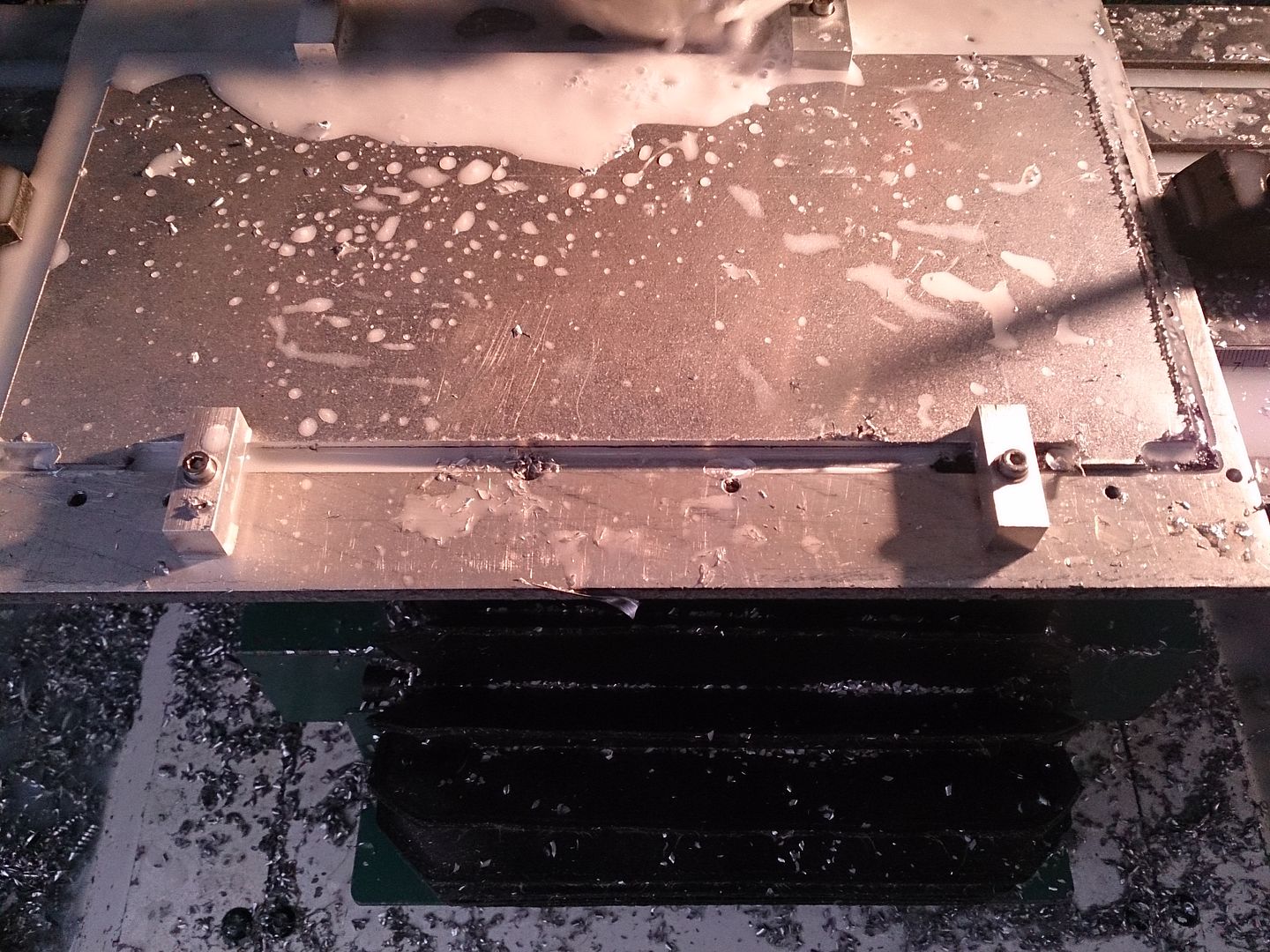

a few pics of the new toy

and the most boring cnc video ever!

Eat Sleep Lase Repeat

Nice buy Andythat's a mint lookin rig!

Regarding the slitting saw. They are a great investment. They come in real handy often for small little parts where you machine a bunch of the out of one block and you can cut them off from the base as your last operation.

Just run them slow and heaps of coolant/cutting fluid to stop the sides rubbing and flush out the chips.

Makes sure the head is clocked up straight but don't fret if you see a little runout and it wobbles slightly as they almost always do a little.

Good luck and have fun with your new beasty.

Kit

may get one and give them at go at some point

I love the fact I can get a big heat sink in the cnc and still use my tapping head, awesome

Eat Sleep Lase Repeat

the wife and daughter have been away this week so ive been spending a lot of time in the workshop trying a few new things.

been making an aperture mask

I also made a matching aperture window, I wanted to try sealing it so I purchased some 1mm thick o-ring cord. and well the results are very good, I machined a 1mm slot all the way round using a 1mm bull nose cutter and it fits like a dream.

I also needed to machine some 2mmm thick ally plate so had to make a big jig. the trick is how to machine is as one so I get nice smooth edges all round.

well made some clamp and you run the machine and go round or in this case over the clamps

then one by one undo the clamps and move them to the hole next door and machine the bits you missed. this way nothing has moved a mm and you get a smooth finish all round

Eat Sleep Lase Repeat