heavy handed is the best way to test stability

just received the new springs, I'm hoping this is the final element of the project. it would be nice to put it to bed and move onto other things

heavy handed is the best way to test stability

just received the new springs, I'm hoping this is the final element of the project. it would be nice to put it to bed and move onto other things

Eat Sleep Lase Repeat

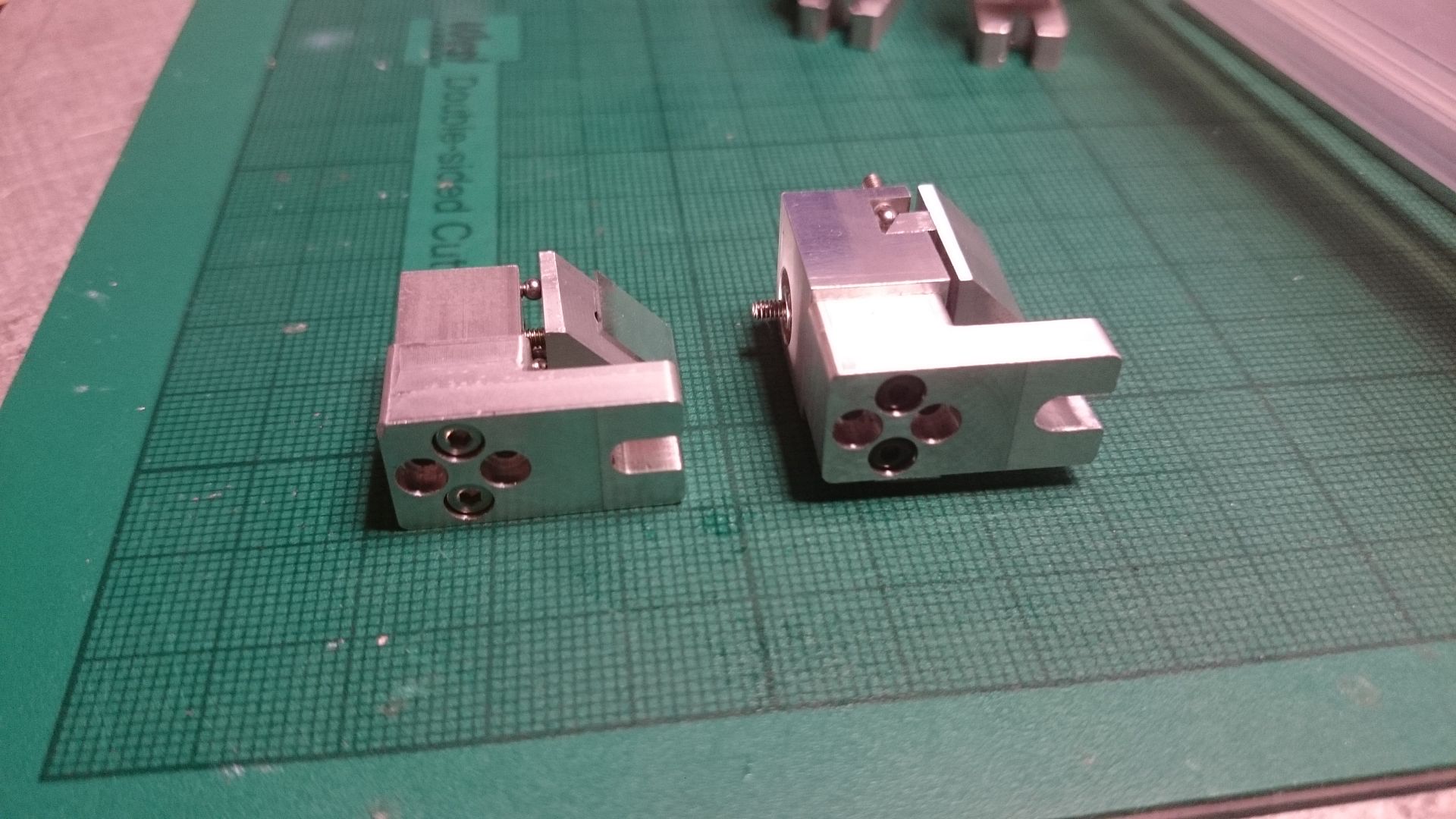

new springs arrived and the top adjustable mirror mount is finished

ive also been working on another spring loaded mount the adjustments from the back. this is a normal 10mm wide mount.

Eat Sleep Lase Repeat

I once used a few nylon washers instead of springs.

Your mounts is very usable but too thick for compact modules )))

Do you use some kind paste or grease for screws?

the top adjustable is only 14mm wide, 25mm long and 26mm high, so its not big

the other one is the same size as a brass flex mount

don't understand what you mean about grease for screws?

Eat Sleep Lase Repeat

I have noticed that over time the aluminum sticks to the screws, if alloy without T markdon't understand what you mean about grease for screws?

oh ok, which screws are you referring to?

how does it stick to a screw, do you mean the thread of a screw?

Eat Sleep Lase Repeat

I mean the adjustment screws of course ))

yes, prestressed threaded connections need lubrication if they adjustable. Some brass alloys contains graphite for thishow does it stick to a screw, do you mean the thread of a screw?

if the ally sticks to the thread of the adjustment screws then surely that locks things in place ;-)

Eat Sleep Lase Repeat

Never mind, I just carp

lol, to be honest I don't think ive ever had ally stick to the thread of a screw. im not saying it doesn't ive just not had it

Eat Sleep Lase Repeat