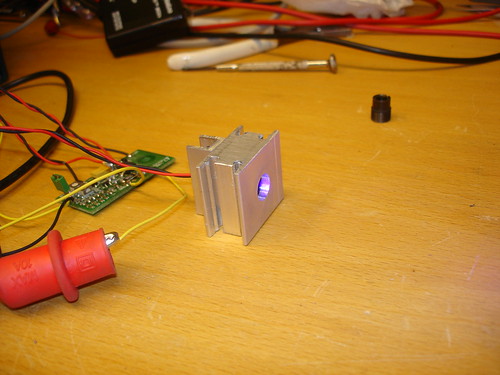

Thats a nice NO NONSENSE mount!!

What optics did it use?

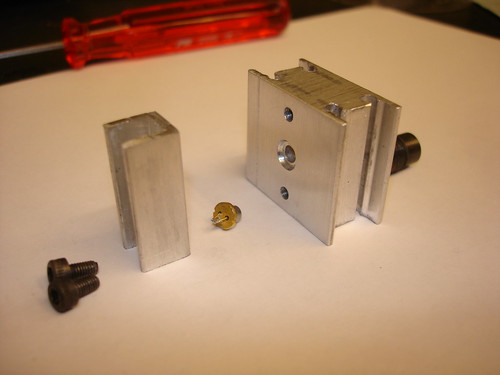

The DX unit has a brass holder.

That type doesn't use the PRESS IN method.

You place the diode inside the mount en then screw on a small brass plug that holds the diode in place.

It a nice system.. but its a bummer the optics are crap.

Reply With Quote

Reply With Quote

dave

dave